Managing a commercial facility isn’t just about keeping the lights on. It’s about orchestrating a complex symphony of systems, people, and processes that keep your building running smoothly—day in, day out. Whether you’re overseeing a bustling office complex in Dublin or managing a sprawling industrial facility, having a comprehensive facility management checklist isn’t just helpful. It’s essential.

Here’s what the data tells us: unplanned downtime costs facilities around $25,000 per hour in 2024, according to a MaintainX survey of over 1,000 maintenance professionals. For larger manufacturing operations, Aberdeen Research found that unplanned downtime can cost up to $260,000 per hour. These aren’t just numbers—they’re wake-up calls.

The good news? A well-crafted maintenance checklist can transform these statistics. Companies can save between 12% and 18% by using preventive maintenance over reactive maintenance, and each dollar spent on PM saves an average of $5 later on. Additionally, Facilities Net found that proactive maintenance reduces downtime by an average of 17.8% compared to reactive maintenance.

Consider what happened to a major Dublin tech company last year. A simple HVAC system failure during a heatwave led to server room overheating, forcing a complete shutdown for 48 hours. The culprit? Clogged filters that hadn’t been checked in months. A basic maintenance checklist would have flagged this issue weeks before it became critical.

Your facility management checklist ensures nothing falls through the cracks. It transforms chaos into order, helping you minimise risks, reduce energy consumption, and keep your facility running like clockwork. More importantly, it protects your bottom line.

Your daily inspection checklist forms the backbone of effective facilities management. These aren’t time-consuming tasks—most can be completed during a morning walk-through.

Start with your security system checks. Are all access points functioning properly? Is your CCTV recording clearly? Even smart building security systems need daily verification to ensure they’re operating as intended.

Next, give your HVAC system a quick once-over. Listen for unusual noises, check that temperatures are consistent across zones, and ensure vents aren’t blocked. These simple checks can prevent major breakdowns.

Don’t forget the basics: inspect walkways and parking lots for hazards, verify emergency exits are clear, and confirm fire extinguishers are accessible and properly mounted. It sounds mundane, but these daily maintenance tasks are your first line of defence against accidents and compliance issues.

Weekly maintenance tasks require a bit more depth. This is when you roll up your sleeves and inspect systems more thoroughly.

Your HVAC inspection should now include checking filters, examining vents for dust build-up, and testing thermostat responsiveness. A clogged filter might seem trivial, but it forces your system to work harder, increasing energy consumption and shortening equipment lifespan.

Plumbing systems need attention too. Check under sinks, around toilets, and near water heaters for any signs of leaks. Even a small drip can waste thousands of litres annually—not to mention the potential for water damage.

Electrical components deserve careful visual inspection. Look for frayed wires, loose connections, or signs of overheating. If something looks amiss, don’t play electrician—call in the professionals.

Finally, implement your cleaning checklist. This isn’t just about aesthetics; regular cleaning prevents the build-up of debris that can affect equipment performance and create safety hazards.

Monthly tasks dig deeper into your facility’s operations. This is when you conduct thorough audits and address items that don’t need weekly attention but can’t wait for annual reviews.

Test your fire alarm system without fail. Document each test meticulously—you’ll need these records for compliance audits. Similarly, check carbon monoxide detectors and replace batteries as needed.

Machinery and equipment need operational audits. Check for unusual wear patterns, listen for changes in operating sounds, and verify that safety features function properly. Prevention is always cheaper than repair.

Review your energy consumption data. Are there unexpected spikes? Patterns that suggest equipment inefficiency? This analysis can reveal problems before they manifest as failures.

Don’t neglect your landscape maintenance either. Overgrown vegetation can block security cameras, create hiding spots, and even damage building exteriors. Plus, a well-maintained landscape sends a message about your facility’s overall care.

Your HVAC system is arguably your facility’s most critical component. When it fails, everything else suffers. Here’s what your HVAC maintenance checklist must include:

Filter replacement isn’t negotiable. Depending on your environment, filters need changing monthly or quarterly. Dusty industrial settings? Monthly. Clean office environment? Quarterly might suffice. But here’s the thing—checking them regularly lets you adjust schedules based on actual conditions, not arbitrary timelines.

System efficiency checks go beyond just “is it working?” Monitor energy usage patterns, check refrigerant levels, and ensure drain lines are clear. These preventive maintenance tasks extend equipment lifespan significantly.

Always follow manufacturer guidelines for maintenance intervals. Yes, they’re conservative, but they’re also your warranty lifeline. Document everything—when you checked what, what you found, what you did about it. This isn’t bureaucracy; it’s smart facility management.

Watch for these repair indicators: unusual noises (grinding, squealing, banging), inconsistent temperatures, frequent cycling, or visible ice formation. Catching these early prevents those painful emergency repair bills.

Your security system protects everything else. It deserves meticulous attention. Start with access control functionality—test card readers, keypads, and biometric scanners. A faulty reader at 2 AM is more than inconvenient; it’s a security breach waiting to happen.

CCTV systems need more than just “are they on?” checks. Verify camera positioning hasn’t shifted, clean lenses for clarity, and ensure recording quality meets your needs. You might come across interesting CCTV camera facts during your research, but focus on functionality first.

Test intruder alarms regularly, including motion sensors, door contacts, and glass-break detectors. Understanding how intruder alarm monitoring works helps you identify potential issues before they compromise security.

Check the integration between your security and fire alarm systems. During an emergency, these systems must work in harmony—security doors releasing for evacuation whilst maintaining audit trails.

Don’t overlook physical wiring and connections. Rodents, weather, and wear can damage cables. A visual inspection during your checklist review can prevent system failures. Ensure everything continues to function properly by addressing issues immediately.

Fire safety isn’t just about compliance—it’s about protecting lives. Your fire extinguishers need monthly visual inspections: Are they properly mounted? Fully charged? Unobstructed? Annual professional servicing is mandatory, but monthly checks catch problems early.

Emergency lighting must work when needed most. Test monthly, document results, and replace failed units immediately. Same goes for your fire alarm system—weekly tests might seem excessive until you need that alarm to save lives.

Stay current with safety regulations. Health and safety requirements evolve, and ignorance isn’t a defence during inspections. Create a compliance calendar marking inspection dates, certification renewals, and regulation updates.

Maintain meticulous health and safety documentation. Every test, every inspection, every repair—document it all. When auditors arrive (and they will), comprehensive records demonstrate not just compliance but commitment to safety.

Understanding the importance of fire alarm systems goes beyond ticking boxes. It’s about creating a culture where safety is paramount.

Think of your maintenance checklist as an early warning system. Those small anomalies you notice during routine inspections? They’re breadcrumbs leading to bigger problems.

Regular inspections reveal patterns invisible in isolation. That HVAC unit cycling more frequently? Could indicate refrigerant loss. Doors sticking slightly? Might signal foundation settling. Your maintenance checklist helps connect these dots before they become expensive surprises.

Tracking maintenance data helps identify trends. Maybe certain equipment fails predictably after specific intervals. Or perhaps energy consumption spikes correlate with particular weather patterns. These insights let you schedule preventive maintenance precisely when needed—not too early (wasting money) or too late (risking failure).

Use audits strategically to improve efficiency. Don’t just check boxes; analyse what you find. Why does that particular area always need more cleaning? Could better entrance matting reduce the issue? This analytical approach transforms routine tasks into continuous improvement opportunities.

Most importantly, regular maintenance prevents costly repairs. That €200 belt replacement scheduled during routine maintenance? It prevents a €10,000 compressor failure. The maths is simple, but the discipline required isn’t.

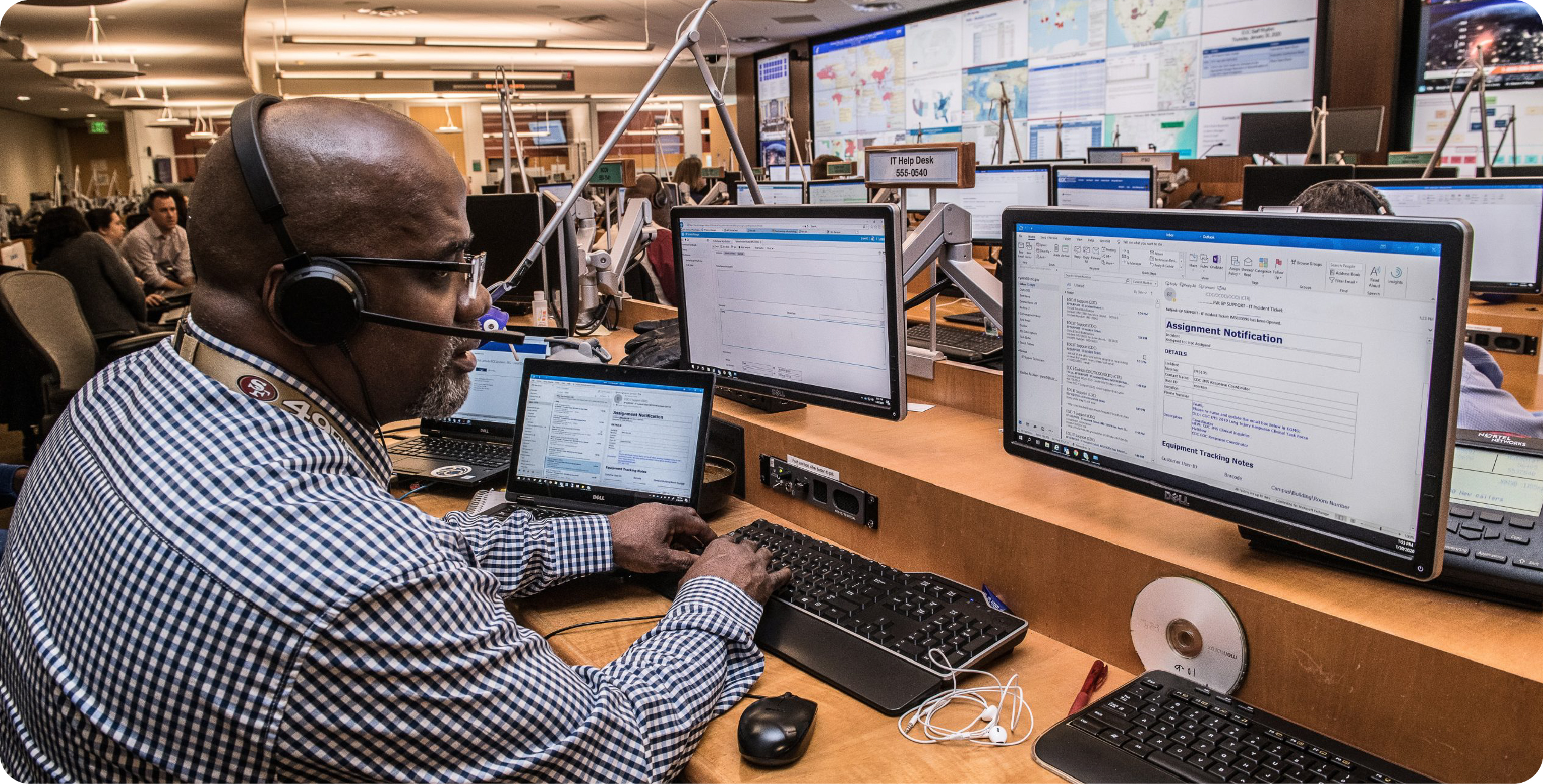

Successful facility management isn’t just about following checklists—it’s about creating systems that work. Implementing a work orders system brings order to chaos. Whether it’s a simple spreadsheet or sophisticated facilities management software, tracking who does what, when, creates accountability and prevents tasks from falling through cracks.

Modern facilities management software can revolutionise your operations. The best management software doesn’t just digitise paper checklists; it provides insights, automates scheduling, and creates audit trails. But remember—technology enhances good processes; it doesn’t fix bad ones.

Train your staff thoroughly on inspection protocols. The best checklist fails if people don’t understand why they’re checking things. When your team understands that checking those fire extinguishers could save lives, they’ll do it properly.

Documentation might feel tedious, but it ensures optimal performance over time. Every inspection, every repair, every anomaly—document it. This historical data becomes invaluable for troubleshooting, budgeting, and proving due diligence.

Consider security gate automation as part of your best practices. Automated systems reduce human error and provide better access control tracking.

Let’s be honest—managing a facility with spreadsheets and paper checklists is like trying to navigate Dublin with a 1950s map. It’s possible, but why make life harder?

Modern facilities management software can streamline every aspect of your operation. Maintenance scheduling becomes automated, sending reminders before tasks are due. Compliance tracking transforms from a nightmare into a dashboard you check over morning coffee.

Work orders flow seamlessly from identification to completion. Staff report issues via mobile apps, managers assign tasks instantly, and completion confirmations update in real-time. This efficiency translates directly to reduced downtime and lower costs.

Asset and equipment lifespan tracking prevents surprises. The software monitors usage patterns, maintenance history, and manufacturer recommendations to predict when replacement makes more sense than repair. No more emergency purchases because something failed unexpectedly.

Energy management features can yield significant savings. Building Energy Management Systems typically deliver double-digit percentage improvements in efficiency. One Dublin museum reduced energy costs by nearly a third through better monitoring and control—imagine what similar attention could do for your facility.

Mobile inspection applications have revolutionised facility management. Instead of clipboards and illegible handwriting, inspectors use tablets or smartphones. Photos document issues instantly, voice-to-text captures detailed notes, and GPS confirms inspection locations.

Real-time reporting changes everything. Previously, an inspector might note a security issue on Friday afternoon, type up the report Monday, and submit it Tuesday. By Wednesday, when maintenance arrives, the problem has worsened. Now? Issues identified at 9 AM can be resolved by lunch.

Integration with existing security systems amplifies these benefits. Your inspection app talks to your CCTV system, access control, and building management systems. Spot an issue on camera? Generate a work order without leaving your desk.

Data analytics transforms reactive management into predictive maintenance. Machine learning algorithms analyse your inspection data, identifying patterns humans miss. That bearing that fails every 18 months? The system will flag it at month 16.

Navigating health and safety regulations feels like solving a Rubik’s cube blindfolded. But it doesn’t have to be overwhelming. Start with the basics: know which regulations apply to your facility. Manufacturing faces different requirements than offices. Healthcare has unique challenges.

Meeting health and safety standards requires systematic approaches. Create detailed checklists for each regulatory requirement. Include not just what to check, but how to verify compliance and what documentation to maintain.

Don’t forget about accessibility requirements. While the Americans with Disabilities Act might be US legislation, Irish facilities must comply with similar local requirements. Regular audits ensure your facility remains accessible to all.

Documentation best practices save headaches during inspections. Organise records logically—by system, date, or regulation. Digital storage with proper backups prevents loss and enables quick retrieval. When inspectors arrive, confidence comes from knowing every document is at your fingertips.

Healthcare facilities can’t approach compliance like retail stores. Patient safety, infection control, and medical equipment maintenance create unique challenges. Your facility management must align with healthcare-specific regulations whilst maintaining general building compliance.

Educational institutions balance safety with accessibility. Students need protection without feeling imprisoned. Regular safety drills, secure access control, and age-appropriate security measures require careful planning.

Manufacturing facilities juggle multiple compliance requirements. Environmental regulations, worker safety, equipment certifications—each demands attention. Your facility management checklist must address them all without compromising productivity.

Retail environments face unique security challenges. Customer safety, loss prevention, and employee protection intersect. Consider incorporating a till fraud detection system as part of your comprehensive security approach.

Breaking the reactive maintenance cycle requires commitment and strategy. Yes, fighting today’s fires feels urgent, but preventing tomorrow’s saves money and stress.

Start by identifying breakdown patterns. Which equipment fails repeatedly? When? Under what conditions? This analysis reveals where proactive maintenance provides the biggest returns.

Build your proactive approach gradually. Don’t try revolutionising everything simultaneously. Pick one system—perhaps HVAC—and implement comprehensive preventive maintenance. Document the results: reduced emergency calls, lower repair costs, improved reliability. Use this success to justify expanding the programme.

Regular maintenance minimises downtime more effectively than any emergency response team. A well-maintained facility rarely experiences those crisis moments that derail operations and budgets.

Cost comparisons tell the story. Reactive maintenance might seem cheaper—until you factor in emergency rates, expedited parts shipping, lost productivity, and shortened equipment life. Proactive maintenance requires upfront investment but pays dividends long-term.

Every facility ages, but smart management slows the process. High-traffic areas need special attention—entrances, corridors, lifts. These spaces endure constant use and show wear first.

Equipment lifespan optimization isn’t about babying machinery. It’s about consistent care: proper lubrication, correct operation, timely repairs. That conveyor belt rated for 10 years? With good maintenance, it might last 15. Without it, you’re lucky to get seven.

The repair versus replace decision tortures facility managers. Here’s a framework: If repair costs exceed 50% of replacement value and the equipment is past 75% of expected lifespan, replacement usually makes sense. But consider downtime, energy efficiency improvements, and technological advances too.

Tracking maintenance needs over time reveals resource requirements. Maybe certain equipment needs attention every autumn. Or perhaps specific areas require deep cleaning quarterly. This knowledge enables better budgeting and scheduling.

Your facility isn’t generic, so why should your checklist be? Start with universal requirements—fire safety, security, HVAC—then customise based on your specific needs.

Consider seasonal variations. Irish weather demands different summer and winter preparations. Heating systems need autumn servicing before winter demands peak. Air conditioning (when you have it) requires spring attention. Your checklist might include weather-stripping inspections before winter and drainage clearing before autumn storms.

Emergency response protocols belong in your checklist too. Not just “what to do” but “who to call,” “where to find,” and “how to document.” When crises hit, clear procedures prevent panic.

Vendor management often gets overlooked. Your checklist should track contract renewals, performance reviews, and certification validations. That lift maintenance company’s insurance expires next month? Your checklist should flag it.

Getting stakeholder buy-in requires demonstrating value. Don’t present your facility management checklist as another bureaucratic burden. Show how it prevents problems, saves money, and simplifies everyone’s job.

Training facility managers goes beyond showing them the checklist. Explain the why behind each item. When people understand that checking door seals prevents energy waste and improves comfort, they’re more likely to do it properly.

Ensuring consistent execution requires the right mix of accountability and support. Regular audits verify checklist completion, but they should identify training needs, not just compliance failures.

Measure your checklist’s effectiveness through key metrics: equipment downtime, emergency repair frequency, energy consumption, compliance audit results. When these improve, your checklist is working.

Review your checklist quarterly, but update it whenever regulations change, new equipment arrives, or incidents reveal gaps. An annual comprehensive review ensures nothing becomes outdated.

Inspection checklists verify condition and identify issues. Maintenance checklists guide actual servicing tasks. Think of it as “checking” versus “doing.”

Software digitises tasks, automates scheduling, provides mobile access, captures photos, generates reports, and creates audit trails. It doesn’t just replace paper—it transforms the entire process.

Life safety systems (fire alarms, emergency exits), security systems, and HVAC top the list. These protect people and maintain operational conditions.

Regular regulatory reviews, industry association resources, and professional consultations keep you current. When in doubt, consult experts.

Digital systems excel here, but even simple spreadsheets work. The key is consistency—record task, date, person, findings, and actions taken.

Include energy-focused items: check for air leaks, clean HVAC filters, verify lighting controls, inspect insulation, and monitor consumption patterns. Small fixes yield surprising savings.

Well-maintained facilities share certain characteristics. Equipment runs smoothly, energy costs stay predictable, and emergency repairs become rare. But how do you measure this objectively?

Track key performance indicators religiously. System efficiency metrics like HVAC runtime ratios and energy consumption per square metre reveal improvement opportunities. Preventive maintenance compliance rates—tasks completed on schedule—indicate program health.

Cost savings from preventive maintenance justify your efforts. Document every prevented failure, each extended equipment life, all energy savings. When budget discussions arise, these numbers tell your story.

Compliance audit success rates provide external validation. When inspectors consistently find everything in order, your checklist is working. More importantly, you’re protecting your organisation from liability.

Your maintenance checklist should evolve constantly. Regular reviews reveal what’s working and what isn’t. Maybe monthly HVAC filter checks prove excessive, but weekly security system tests catch issues others miss.

New regulations demand checklist updates. Stay informed through industry associations, regulatory newsletters, and professional networks. Ignorance isn’t just risky—it’s expensive.

Facility needs change over time. That storage area converted to offices? It needs different maintenance now. The new manufacturing line? It brings unique requirements. Your checklist must adapt.

Learning from maintenance data drives improvement. Those recurring issues? They indicate systemic problems. Address root causes, not just symptoms, and watch your maintenance burden decrease.

While this checklist helps you manage every aspect of your facility, the security and fire safety components require specialised expertise. That’s where MJ Flood Security comes in.

As an Irish-owned and operated systems integrator, we provide the security infrastructure that makes your facility management checklist actually work. Our comprehensive solutions include:

Security Systems That Protect Your Assets

Fire Safety Systems That Save Lives

Smart Building Integration: Our smart building technology solutions help streamline your facility operations, from visitor management to workplace optimisation. These systems integrate seamlessly with your existing infrastructure, providing the data and control you need for effective facility management.

With over 60 years of combined experience and a network of branches across Ireland, we understand the unique challenges Irish businesses face. Our qualified engineers don’t just install systems—they design solutions tailored to your specific facility requirements.

Why Facility Managers Choose MJ Flood Security:

Your facility management checklist is only as good as the systems supporting it. When it comes to security and fire safety—critical components of any facility—you need a partner who understands both the technology and the regulations.

Ready to ensure your security and fire safety systems support your facility management goals? Contact us today at 01 689 6390 to schedule a free consultation and site survey. Let’s discuss how our security solutions can strengthen your facility management programme.